KEP

KEP

Fully automatic chamber filter press with automatic sludge detection, precisely adjustable drying degree of filter cakes and Siemens PLC with touchscreen colour display.

Function

Chamber filter presses are designed for filtration and dehydration of already concentrated process water suspensions.

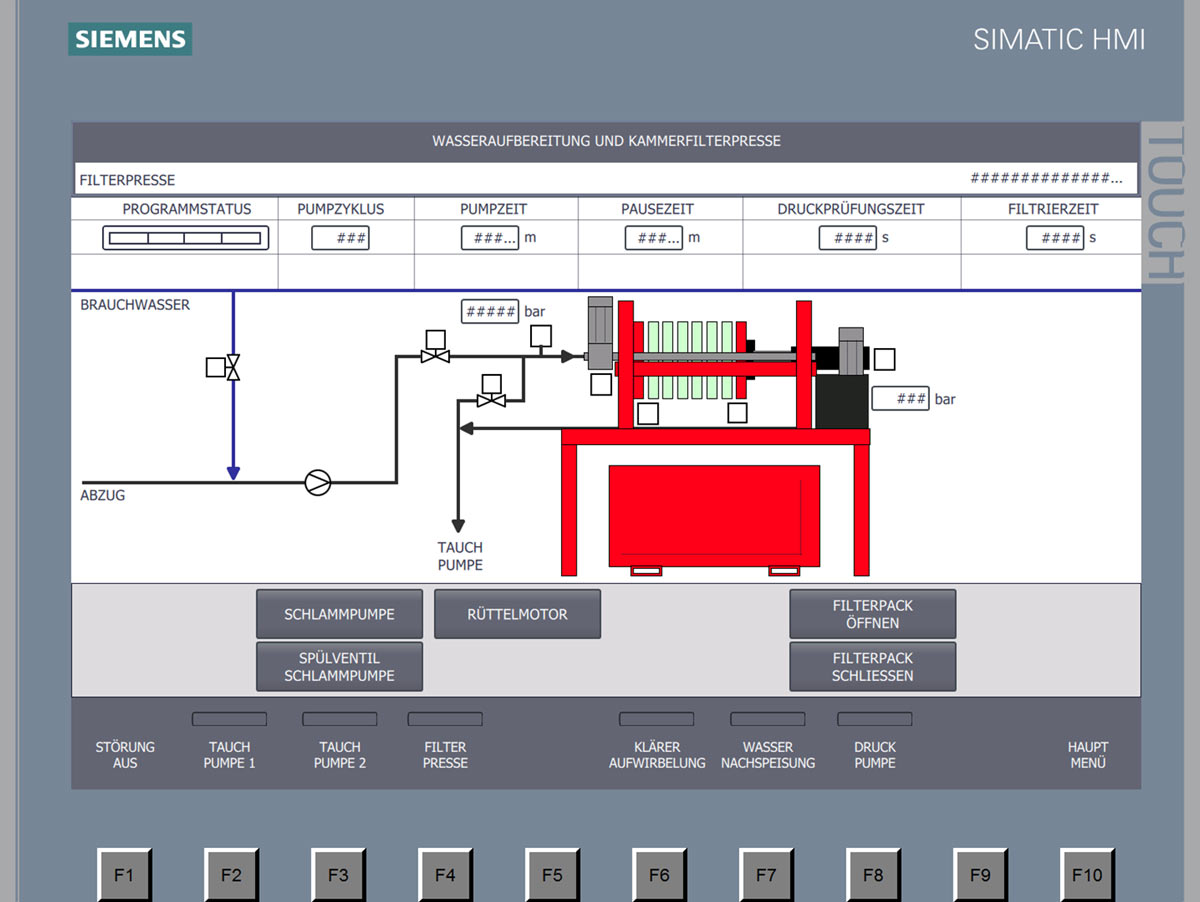

The sediment concentrated in the obliquely-arranged lamellar clarifier is pumped to the chamber filter press by means for further dehydration by means of a special diaphragm pump. The filtrate water drains through a droplet channel and is returned to the production circuit. The particles contained in the process water suspension are retained between the filter cloths. The degree of drying of the filter cakes can be individually adjusted and is monitored by a pressure sensor.

If the setting for the degree of drying of the filter cakes is reached, the pressure in the chamber filter press is released through a relief valve and the filter press opens. The filter cakes fall, with the assistance of automatic shaking by means of a gear motor and vibrating shaft, to the container arranged below the chamber filter press.

Then the diaphragm pump, valves and dirty water lines are cleaned via an integrated flushing program. The press then closes and a new cycle can commence.

The chamber filter press adjusts independently to varying volumes of sludge due to automatic sludge detection. As a result, manual adjustment of the press with a varying production load is not necessary.

Chamber filter presses are the most effective and prevalent system in the area of application of the residual moisture dehydration. The drying rate, degree of drying and automation are significantly higher than with bag drying stations.

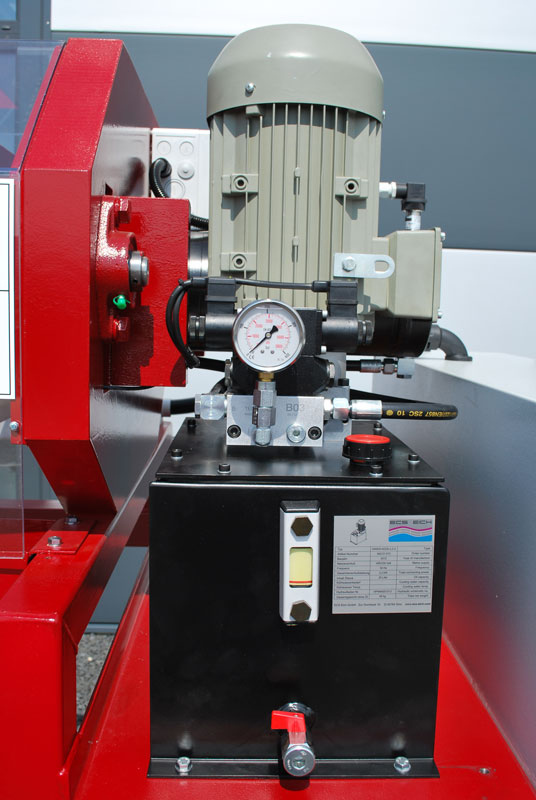

- Hydraulic opening and closing of the filter plates

- Positioning sensor for plate package

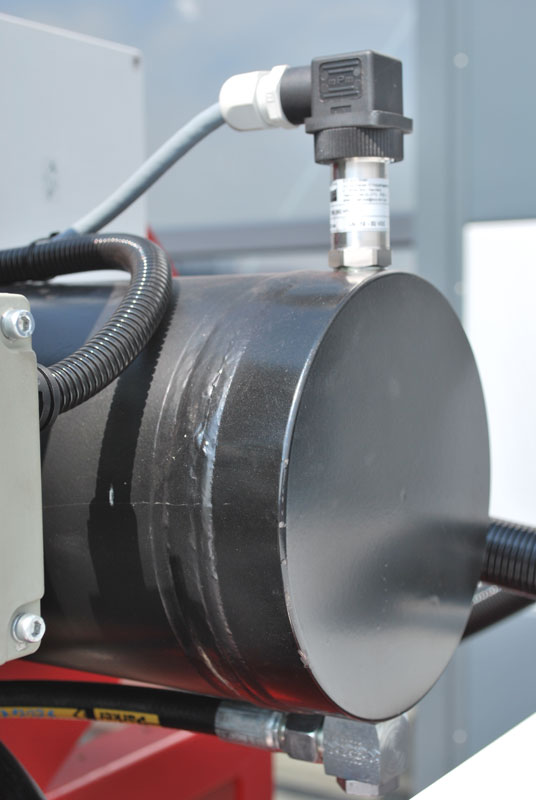

- Hydraulic system pressure make-up via pressure sensor of up to 250 bar

- Compressed air diaphragm pump for abrasive sludge for filling the filter plates

- Fully automatic flushing of the diaphragm pump and lines with fresh water after each press cycle

- Pressure relief of the filter press via pneumatic valve

- Vibrating shaft with gear motor and position sensor

- Fully automatic sludge detection via pressure sensor and control

Control

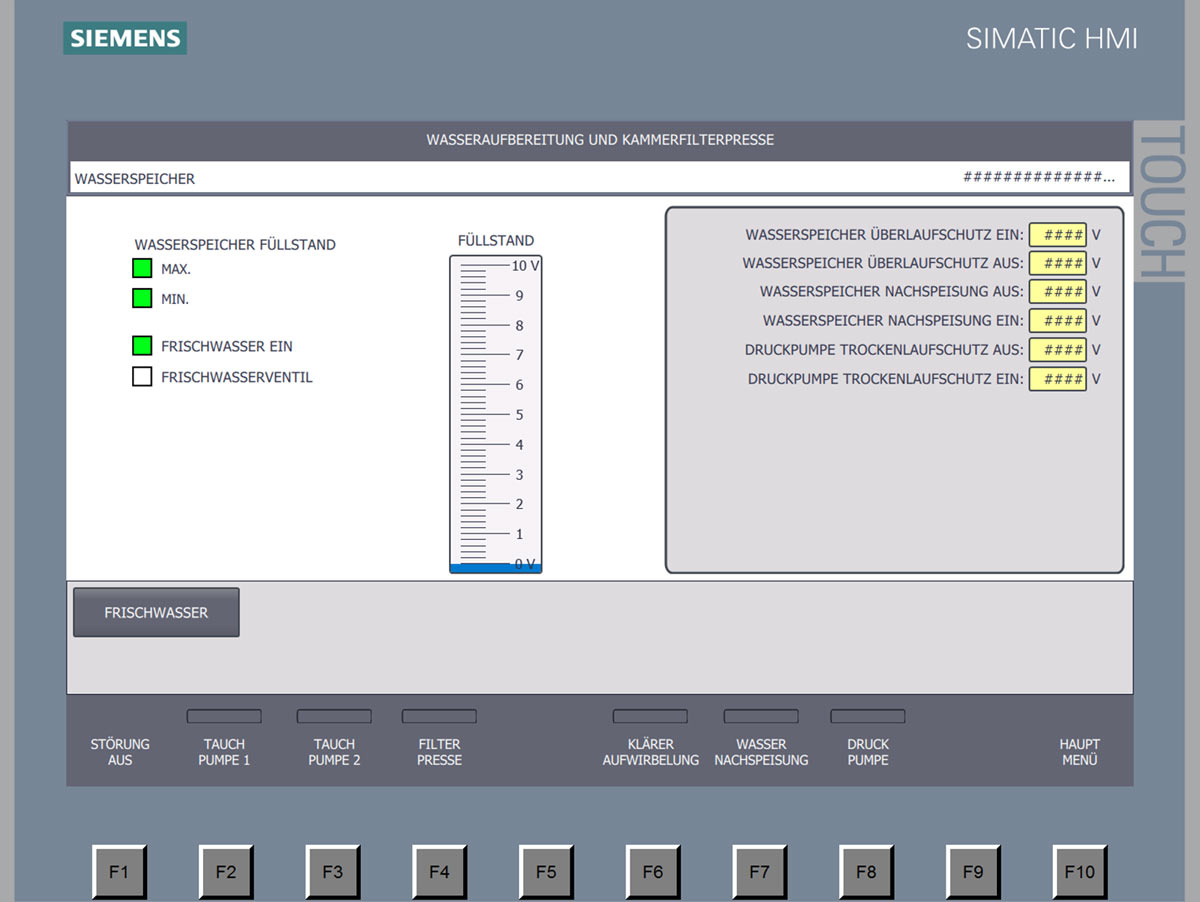

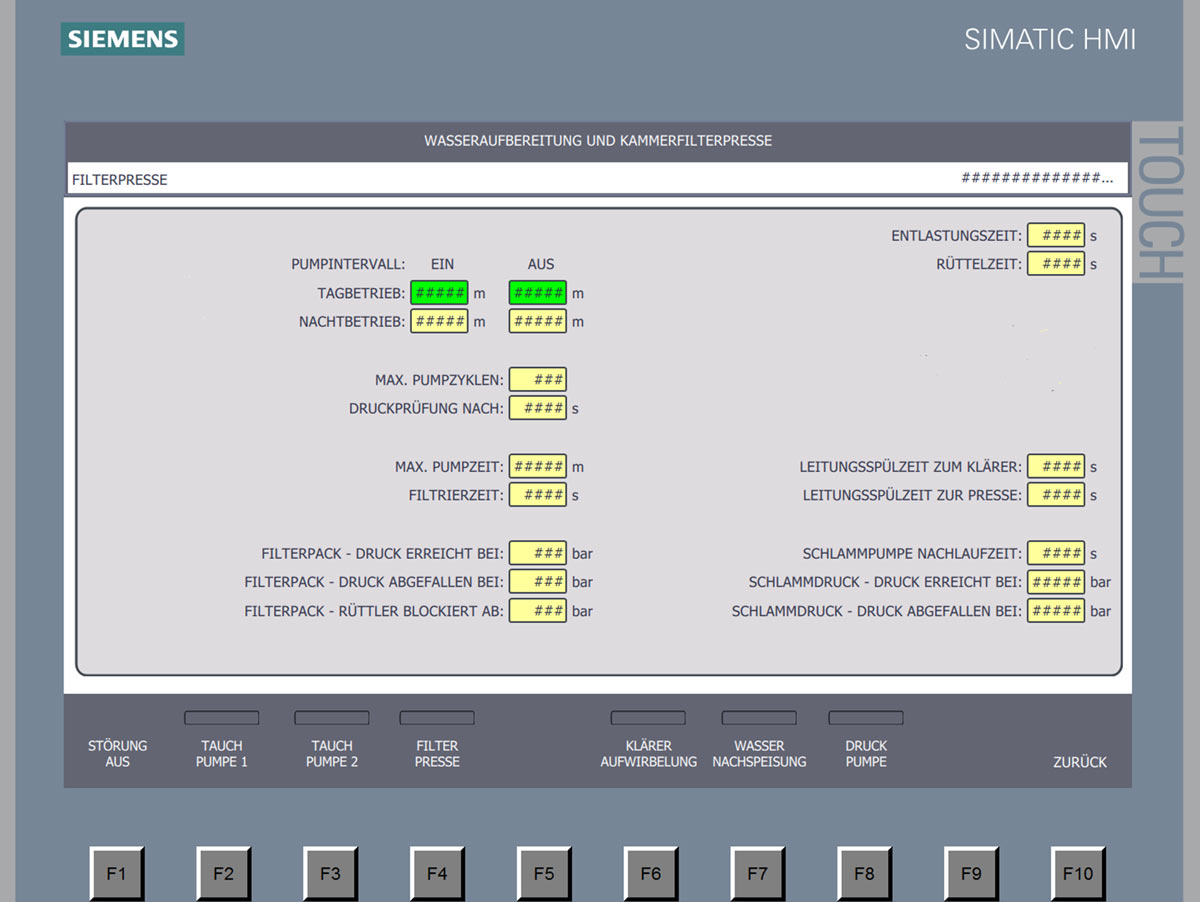

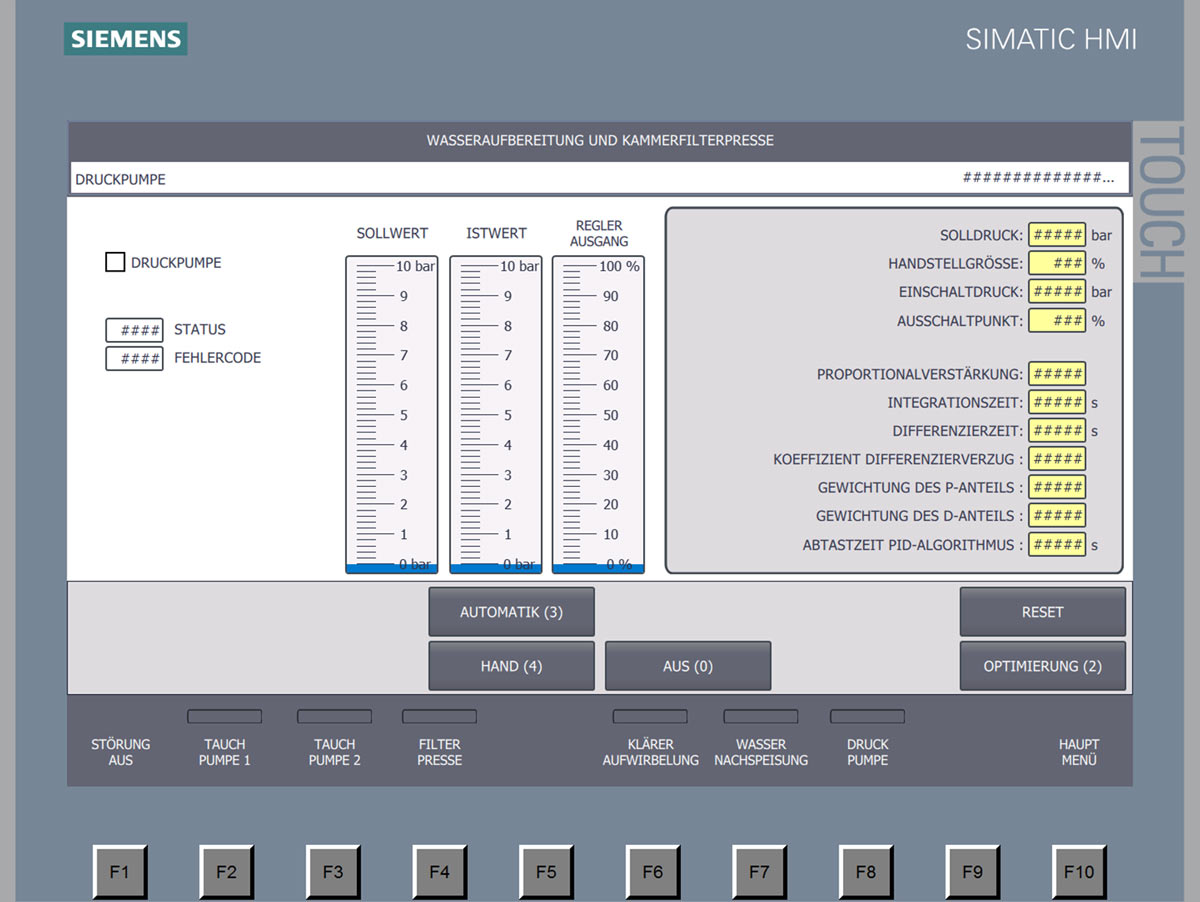

The fully automatic control of KEP filter presses takes place with a Siemens PLC. Operation and visualisation of the flow diagram of all processes and parameters take place via a 12” touchscreen colour display. The press can be adjusted perfectly to the requirements of your operation and your sludge quantities with the comprehensive parameter settings.

Our ECS KEP software is developed in-house and based on our knowledge of process water preparation and our practical experience gathered for over 20 years. Customised software adjustments are possible according to your requirements.

Gallery

Output and dimensions

| Type | Design | Fill quantity |

|---|---|---|

| KEP 400/5 | 5 Filter plates | 16,5 Liter |

| KEP 500/5 | 5 Filter plates | 24,8 Liter |

| Type | Design | Fill quantity |

|---|---|---|

| KEP 500/8 | 8 Filter plates | 43,4 Liter |

| KEP 630/8 | 8 Filter plates | 66,2 Liter |